Machining

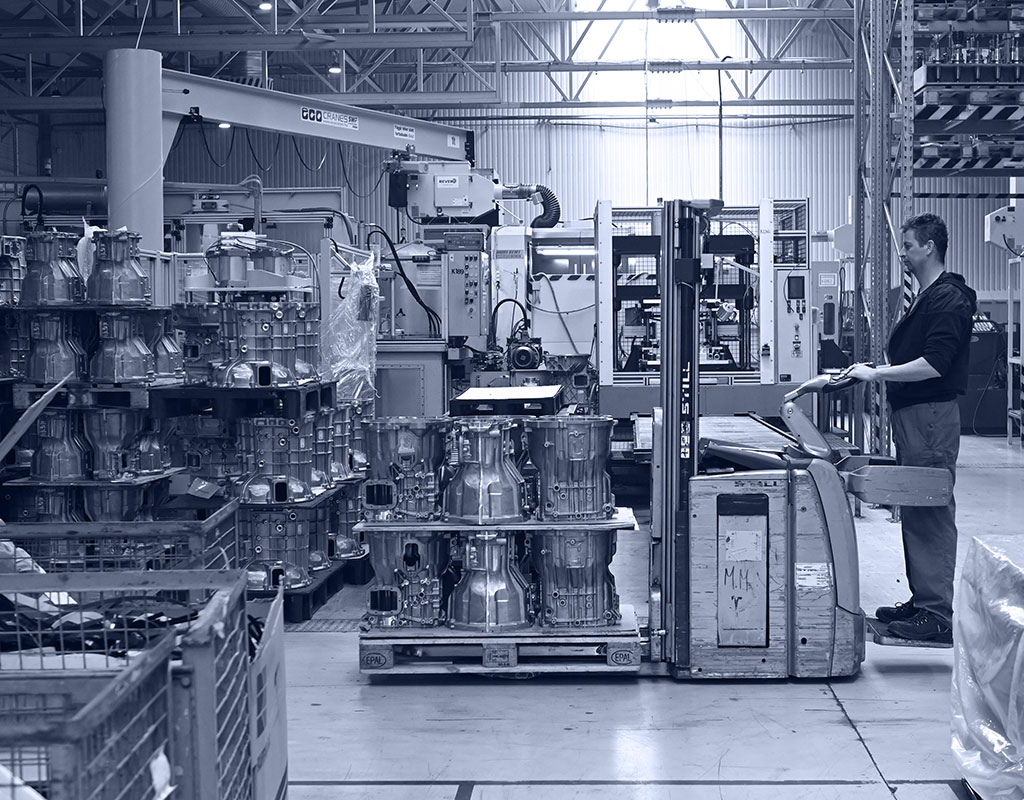

The Kovacs Ltd. extended its production with machining in 2008.

In the interest of the expectations of the steady and precise production, due to the local conditions an environmentally friendly geothermal HVAC system was built at the construction of the production hall. That provides constant temperature and humidity all year round regardless of the season in the warehouse and the entire production hall.

At the purchase of our production equipments we place great emphasis on the selection of machine types. As a result a 24-hour specialist workshop network and fluid management provide the continuous and reliable operation of the machines.

We machine small and big size aluminium parts with the help of our present machine stock. Selecting, planning and manufacturing the tools and equipment required for the production is made by the help of our technology department.

The close relationship between the joint divisions allows the fast and flexible follow-up of the customer needs. The process of the production is monitored by Data Matrix System that is tightly integrated into our SAP system.

As a result of continuous developments in the past years today new and modern Mori Seiki machines provide the realization of the serious engineering work.